Beijing Jingtan Exploration Machinery Co., Ltd.

Contact: Zhang Pengguang

Mobile phone: 13911809966

Email:beitan@beitan.net

Address: Zhangjiawan Industrial Zone, Tongzhou District, Beijing

What are the common failures of new water well drilling rigs?

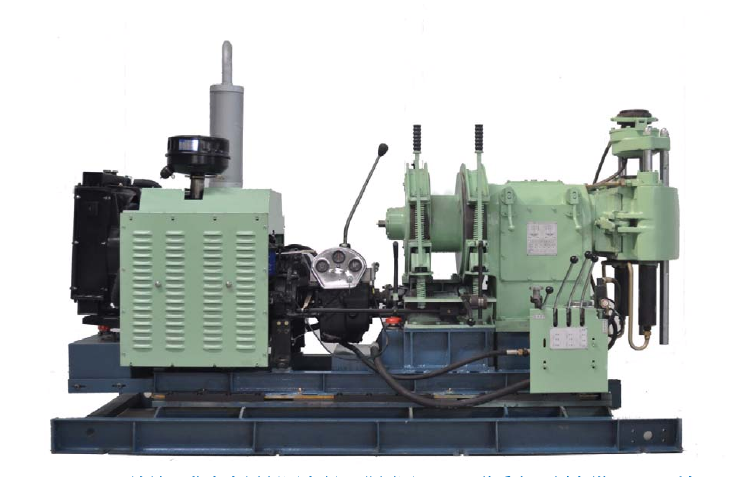

The new water well drilling rig has the characteristics of good maneuverability, compact structure and strong uniformity, and its production and operation are very complicated. We have learned how to increase the service life of the equipment, but in the process of daily application of new water well drilling rigs, some failures will inevitably occur, so let me introduce you to the common failures of the equipment.

1 The slipping of the rig clutch is mainly due to excessive wear or cracking of the friction plate or embrittlement or breakage of the compression spring. The friction plate of the rig should be repaired;

2 The coupling of the new water well drilling rig is hot, and the elastic ring is too worn; the reason is that the coaxiality of the drilling rig and the clutch is poor when it is installed, and the coaxiality of the installation must be increased;

3 The brake of the rig winch slips. The main reason is that there is oil on the surface of the brake belt. The surface of the brake must be cleaned. If there is no oil on the brake, check the gap between the brake belt and the brake wheel Looseness should be adjusted moderately;

4. The oil pump of the drilling rig does not fill with oil or the amount of oil is not enough. First, check whether the amount of oil in the oil tank is insufficient or no oil. If the common faults of the new water well drilling rig that supplies oil to the oil level line are not removed, check Whether the filter is blocked, in addition, you need to see if the air vent of the fuel tank is blocked, or the suction pipe joint is loosened and the air is introduced;

5. The oil pump of the new water well drilling rig is hot and worn, and the oil pump must be repaired and disassembled. The viscosity of the oil is too high or too low. The oil should be used strictly according to the instructions; Installation precision;

6, the oil temperature of the hydraulic system is too high, the oil in the oil tank is too little or the oil pump is damaged, the oil should be supplied or repaired; the working pump should be used reasonably, and the working pressure should be recommended according to the instructions

7. The hydraulic system of the new type water well drilling rig has insufficient pressure. If the pressure regulator is fatigued, adjust the limit nut or replace the spring; if the pressure regulator seat cone is damaged or stuck, remove the pressure regulator sleeve for simple maintenance.